Turnkey Solutions

Wear Plate

Fabrication

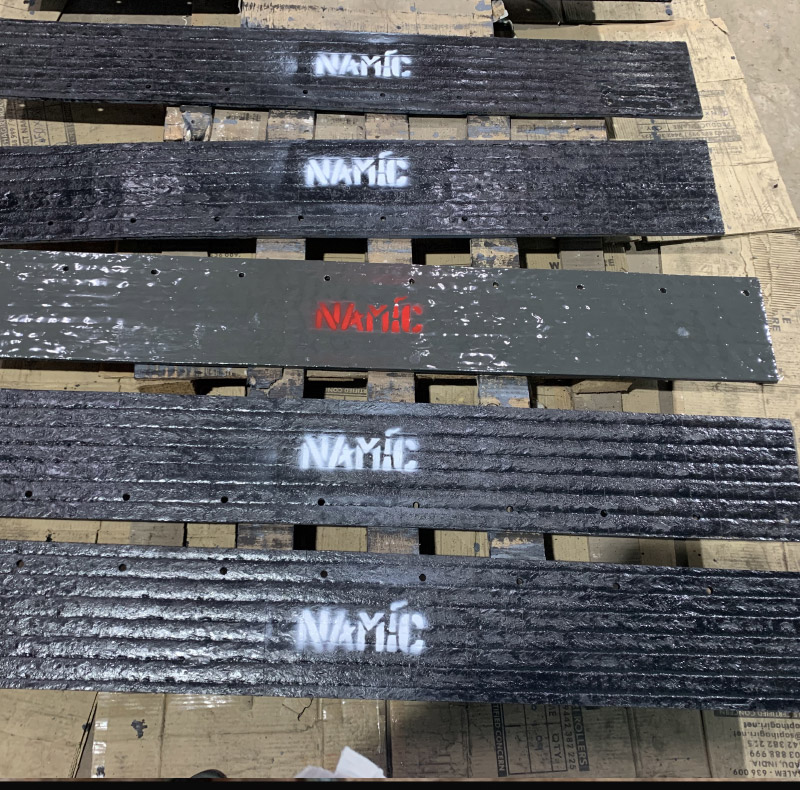

In recent years, maintenance departments have been under increasing pressure to not only reduce operating costs but also to increase operational output and efficiency. The maintenance department can therefore play a critical role in reducing downtime and inventory by selecting longer-lasting components to extend outage intervals.

NAMIC works with a variety of wear plates of several grades. Based on wear phenomena, we fabricate components with wear plates to increase component service life.

NAMIC works with a variety of wear plates of several grades. Based on wear phenomena, we fabricate components with wear plates to increase component service life.

Hardfacing Services

Life-Prolonging Factor

HARDFACING is the concept of “resurfacing worn out parts rather than replacing them”. Hardfacing is the most cost-effective way to extend the service life and efficiency of metal parts that are subject to wear. Simply selecting a high-quality product will not guarantee the desired outcome. Knowing the type of base metal, the type of wear, the welding process, and how to control the application are all critical success factors.

We offer services in our workshops, on customer sites, and on-site, and will advise you on the best welding methods, technologies, and consumables to use. Our goal is to provide exceptional component service life that exceeds the original component’s life expectancy and performance.

We offer services in our workshops, on customer sites, and on-site, and will advise you on the best welding methods, technologies, and consumables to use. Our goal is to provide exceptional component service life that exceeds the original component’s life expectancy and performance.

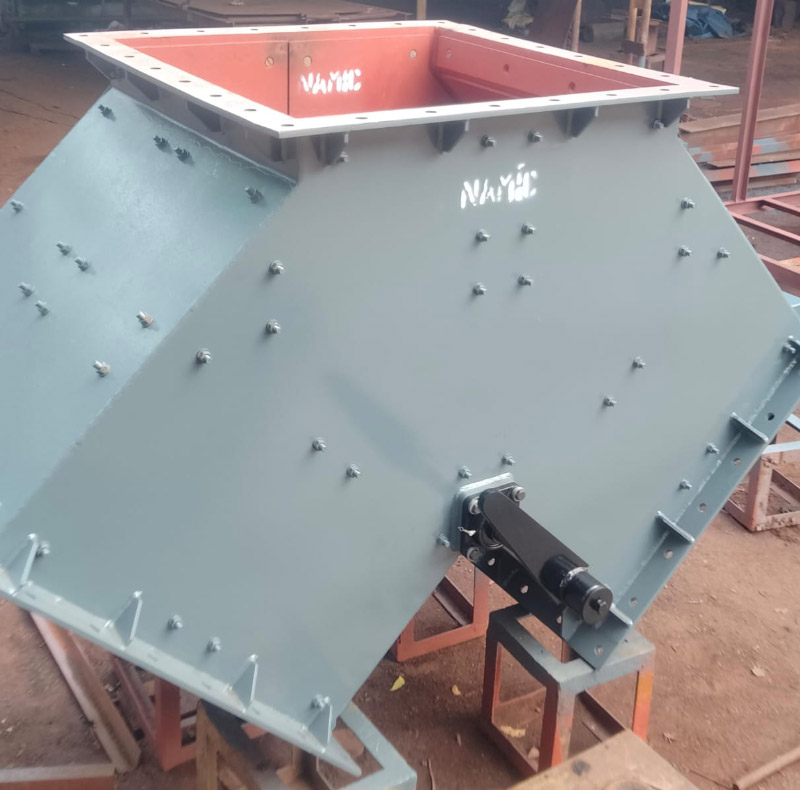

Fabrication & Protective Coatings

Eliminate Corrosion Challenges

The good news is that steel corrosion can be dealt with in a cost-effective and efficient manner. Protective coatings are an easy way to reduce corrosion by limiting a metal’s exposure to a corrosive environment. A critical consideration for protective coatings is ensuring that the coating is well adhered to the metal and remains intact.

The epoxy polymer coatings chosen by NAMIC will withstand environmental and chemical attack corrosion. NAMIC shall also fabricate and coat the job with protective coatings.

The epoxy polymer coatings chosen by NAMIC will withstand environmental and chemical attack corrosion. NAMIC shall also fabricate and coat the job with protective coatings.