Conveyor Solutions

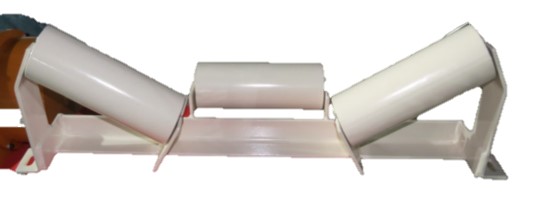

Carrying Idlers

- Carrying Idlers are the most common idlers used on the carry side of the conveyor

- Extending their life expectancy can be a challenge. Our proven seal design and low maintenance rollers lead to less downtime and increased profits.

Impact Idlers

- Damaged conveyor belts can result in downtime and high replacement costs.

- Our impact idlers are designed to be used in impact areas where belt damage is common.

- Impact rolls are designed with rubber tires which absorb impact forces minimizing belt damage.

Self- Aligned Idlers

- Material spillage can occur when conveyor belts become misaligned. Strategically placing self-aligned idlers along the conveyor keep the belt running straight.

- Self-Aligned are like Carrying idlers, but with the ability to pivot at the center and are guided by edge rollers which in turn aligns the belt.

Head Pulley

- The head pulley is located at the discharge point of the conveyor. It usually drives the conveyor and often has a larger diameter than other pulleys.

- For better traction, the head pulley is usually lagged (with either rubber or ceramic lagging material).

Tail Pulley

- The tail pulley is located at the loading end of the belt. It comes with either a flat face or a slatted profile (wing pulley), which cleans the belt by allowing material to fall between the support members.