A Cautionary Tale

When it comes to mining, equipment maintenance is not an option or a luxury. The work is too hard on the machines. When you are using equipment to haul tons of ore or bore into bedrock for hours a day, proper preventive and proactive maintenance is a necessity. Many mining companies have spent millions and sometimes billions of dollars to improve maintenance systems and equipment reliability only to discover little re- turn. Senior managers continue to complain about equipment reliability and maintenance costs.

How to Become Proactive, Not Reactive

People in a reactive mining maintenance environment are busy. The phone con- stantly rings during the workday, and they get calls every night and on the week- ends. The worst part about it is that they deal with the same problems over and over. They never have time to plan because they run from one emergency break- down to the next. I hope to destress their professional lives and give maintenance managers back the time they need to do their jobs with quality, precision, and fore- thought. I want them to enjoy their weekends again.

An Asset Management Journey

Improving Step by Step

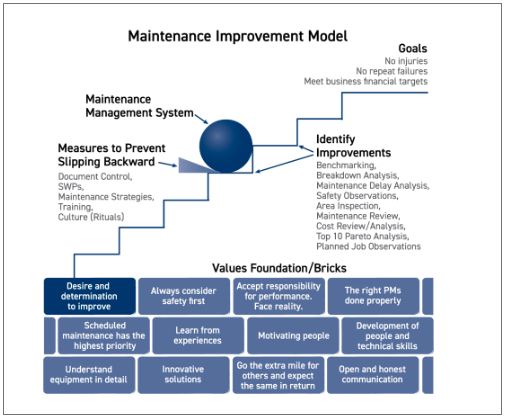

The Maintenance Improvement Model includes several steps we must climb to reach our goal. You can’t reach the top in one step. It requires a series of continual-improvement steps. The list on the right helps us see what we must ad- just, change, and improve. These elements are specific to maintenance.

This connects to another point on the list, the Top 10 Pareto analysis. Vilfredo Pareto developed the 80-20 rule, which essentially says that 80 percent of the effects are caused by 20 percent of the causes. A Pareto chart helps prioritise the top ten problems. Ideally, you will want to chase, to the failure mode, every single breakdown in the top five. When you look at areas of a plant that cause difficulties, you will want to refer to Pareto charts to visualise what areas you should focus on.

Area inspection correlates with safety as well as efficiency. Ensuring your work area is in order is an essential step in an improvement plan. I would have daily inspections of our workshop around a simple set of checks:

•Are all things in their place?

•Are people following procedures?

•Are all the isolations in place?

•Are tools stored correctly?

These inspections create a controlled environment and complement any system such as Five-S. Without the daily discipline to ensure standards are maintained, order usually degrades. Cost review and analysis reinforces the importance of a sound maintenance budget and reviewing performance against that budget. Depending on how actual costs are reported from the Enterprise Resource Planning (ERP) system, compared to how the budget was created, this can be easier said than done. However, it is essential to review costs against both the budget and benchmarks.

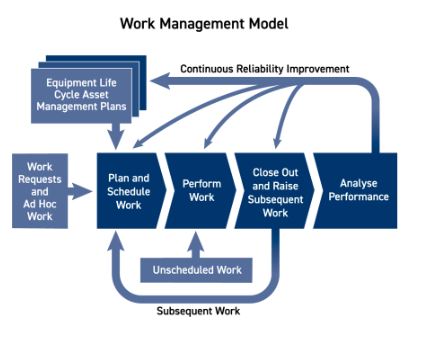

Most organisations have some form of Pipeline Model that shows:

•Planned work

•Scheduled work

•Work performed

•Work completed

•Work closed out

•History

•Subsequent work captured

•Data analysed for performance improvements

The Pain Points

The most significant problems can be categorised into five areas:

•Excessive Unscheduled Downtime—This is the result of too many break-

downs, causing maintenance teams to be reactive.

•Excessive Scheduled Downtime—We must have scheduled downtime, but if

not managed efficiently, it will cause excessive production losses.

•Cost Concerns—These are problems resulting from not meeting a budget,

not controlling costs, or needing to reduce expenses to keep the business vi- able because of low commodity prices.

•People Problems—High turnover of employees can be the starting point for

many other problems.

Excessive Unscheduled and Reactive Downtime Addressing breakdowns is the first step to improving maintenance. Many man- agers think planning and scheduling is the first step to reducing unscheduled downtime, but planning and scheduling only helps once the basics are in place.

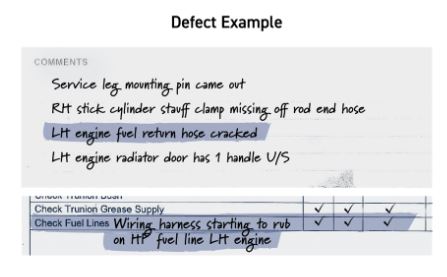

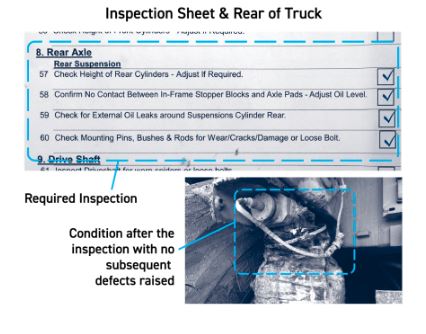

Here are two real-life examples of this problem. These two examples show service sheets listing serious defects. Mechanics reported these problems, but there were no subsequent notifications or work orders raised in their maintenance systems. No one addressed the problem, which could lead to breakdowns or a fire on the equipment.

The first example is a failing fuel hose. Someone inspected the engine on a mining truck and noted that the fuel hose was wearing out. A cracked fuel hose could leak and spray fuel onto the hot parts of the engine and cause a fire. This worn-out fuel hose wasn’t raised as a defect in the system nor repaired immediately during the service.

Budget Overruns and Cost Concerns

Cost controls can become a rub point between owners and maintenance managers. The maintenance manager is often judged for expeditures—some-one is always saying maintenance costs are too high—but this judgment isn’t entirely fair. What measures are executives using to make this judgement? Executives might see expenses go up from one year to the next and think that is a problem. However, equipment life cycles require components to be re- placed at certain intervals, so maintenance expenses legitimately fluctuate from year to year. This should be expected, but this fact is misunderstood by many executives. Budgets are not set with equipment life cycles in mind. What’s more, executives often don’t know how to judge the cost performance of maintenance. They compare sites’ performance based on the cost per product tonne, which is important to the bottom line but not useful as a benchmark.

Executive leaders often don’t know how to judge maintenance costs. They plan on a flat line, but that isn’t possible for a piece of mining equipment. The maintenance cost is going to go up and down from year to year according to the machine’s nor- mal maintenance schedule. You can smooth the expenditure if you have a large fleet, but that’s hard to do on a small site or individual machine basis. About a year ago, I was at a site where management consultants had analysed the cost of all the machines over the past year. We had improved the fleet availability and there was a surplus of trucks. To improve cost performance, the management consultants proposed shutting down a couple of trucks that had cost the most to maintain in the previous year.

Moving tonnes of material is what causes the equipment to wear out and require servicing. However, it is not an apples-to-apples comparison to look at two dif- ferent sites’ maintenance costs per product tonne. One site might have to move a hundred tonnes to get one tonne of product, and another site might only have to move ten tonnes to get the same one tonne. To demonstrate this point, look at the following maintenance cost graphs for several mines. The first shows the mainte- nance costs per product tonne, and the second shows the maintenance cost per total tonne moved. Clearly, the site that looks the worst on a cost-per-product tonne is nearly the best when looking at cost-per-total tonne moved. This site has much higher strip ratios and needs to move more material to make the same amount of product.

Mining companies lose tens of millions of dollars by poorly managing parts, allow- ing components to be lost, damaged, or become obsolete. Managing parts is simple if you document a process for them. However, it’s often difficult to implement the routines across all rosters and between maintenance and supply functions. Use a Five-S structure to set up a process. There are many resources that help you implement a Five-S program. It’s easy to get to the fourth S, but it is essential that you achieve the fifth S and make your system sustainable. Here’s how:

- Sort—Clean up the area and throw away all rubbish.

- Set in order—Make sure there is a place for everything and everything is in its

- place.

- Shine—Focus on maintaining cleanliness.

- Standardise—Establish routines and best practices.

- Sustain—Create a culture of people who care about the work.