Polyurethane Solutions

Polyurethane Liners

Polyurethane liners are primarily used to solve wear issues related to the bulk transport or movement of materials. Simply put, they protect equipment from wear and tear. Like other urethane product applications, urethane liners help prevent machinery maintenance and downtime, offer long-lasting protection, and can be easily customized to meet the specific needs of your industry.

PU Liners is most often selected as the preferred lining because it:

- Helps minimize impact and sliding abrasion damage in abrasive situations.

- Resists corrosion

- Resists many chemicals, including oil, fuel, and grease.

- Helps minimize noise, sound dampening.

- Has a low coefficient of friction.

- Has a high tear strength.

- Resists impingement

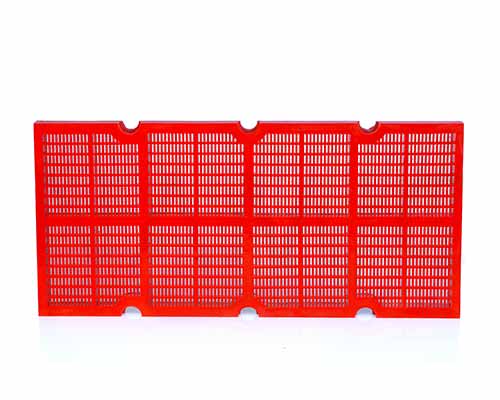

Screen Deck

Polyurethane Screen Panel is commonly used in dewatering and classification of mineral process and construction industries. polyurethane screen panel is manufactured by the processing technology of steel wire covered with polyurethane. It is characterized by firm structure and durability. polyurethane screen panel adopts high-quality polyurethane raw materials, which has excellent elasticity, super wear resistance and good screening efficiency. All polyurethane raw materials and their proportion have been tested and strictly selected, and advanced injection molding technology and precision designed & manufactured molds are used for injection molding, which can guarantee polyurethane screen panel completely customized according to your needs. Opening shape and opening size, screen plate thickness, fixing method, overall size and other elements can be arbitrarily determined.

Belt Scrappers

- Belt Scrapers are used in bulk material handling belt conveyors to avoid material carryback and reduce spillage.

- Clean belts help prevent material build up on pulley & return idlers, thereby reducing maintenance and downtime.

- Belt Scrapers are a cost effective solution for efficient belt cleaning.